Materials Processing Institute

Materials Processing Institute Appoints Diana Mehta To Lead Circular Economy Group

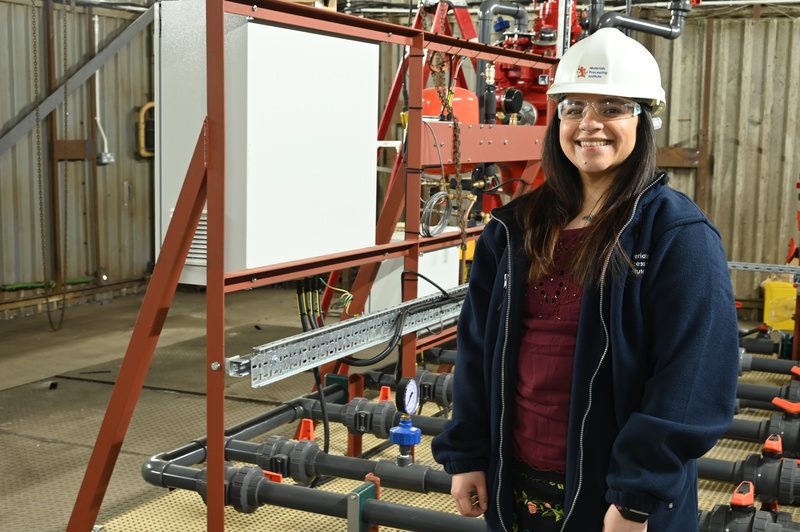

The Materials Processing Institute has appointed Diana Mehta as Group Manager for the Circular Economy.

She joins the Teesside-based Institute from former start-up Britishvolt where she was a Principal Scientist, leading an 11-strong research, innovation and materials team, focusing on battery technology for applications in electric vehicles.

As Group Manager for the Circular Economy, Diana will lead the development of innovations that maximise resource efficiency through manufacturing and process optimisation.

The Group focuses on extracting value from waste, identifying technologies and recovering materials that reduce resource consumption, while also reducing waste generation. It currently works with a range of partners to develop, pilot, and commercialise technologies and processes that support the development of a circular economy.

She gained a PhD in Chemistry at Loughborough University, where she developed, led, and completed research into introducing hydrogen for energy grid decarbonisation. In 2019 she was named as runner-up Female Engineer of the Year by the Women’s Engineering Society.

Prior to joining Blyth-based Britishvolt, where she undertook numerous projects including raw material selection, material development and cell manufacturing, she was Senior Scientist, Battery Materials, at Billingham-based Johnson Matthey, where she led the scale-up of new battery material products.

Diana Mehta said: “I look forward to using my experience in scientific research, the development of low carbon technologies and leading projects from conception in the laboratory through to scale-up to support and implement the Institute’s strategy within the field of circular economy.

“This is a vital area for the UK as the government seeks to cut carbon emissions in order to achieve its 2050 Net Zero target by transforming and decarbonising industry, which not only helps futureproof it, but will allow this country to move away from its reliance on imports.”

Chris McDonald, the Institute’s Chief Executive Officer, said: “Diana has a proven track record in research, innovation, and collaboration with supply chain partners, whilst displaying qualities as a leader with entrepreneurial acumen. As such, she will play a pivotal role in overcoming the challenges in the circular economy to achieving zero waste.”

ENDS

ISSUED ON BEHALF OF MATERIALS PROCESSING INSTITUTE

MEDIA CONTACT: Andrew Douglas 01325 363 436

Photo caption: Diana Mehta joins the Materials Processing Institute as Group Manager for the Circular Economy

Notes to editors:

Materials Processing Institute

The Materials Processing Institute is a research and innovation centre serving global steel and materials organisations that work in advanced materials, industrial decarbonisation, the circular economy, and digital technologies.

The Institute has served as the UK’s national steel innovation centre since 1944 having been set up by Sir Winston Churchill’s wartime government just before D-Day to equip the British steel industry for post-war reconstruction. It will celebrate its 80th anniversary in 2024.

Through collaboration with its customers, the Institute provides a range of technology and R&D based services and consultancy. It also has pilot and demonstration facilities and an SME Technology Centre to support supply chain businesses with the development of new technologies and products.

Works with: steel, metals and alloys, chemical processes, aerospace and defence, energy, mining and quarrying, construction, rail, transport, and infrastructure, offshore, subsea, and nuclear.

The Materials Processing Institute includes developments funded through Tees Valley Combined Authority, through the Local Growth Fund (Growth Deal).

back to Materials Processing InstituteImages